-40%

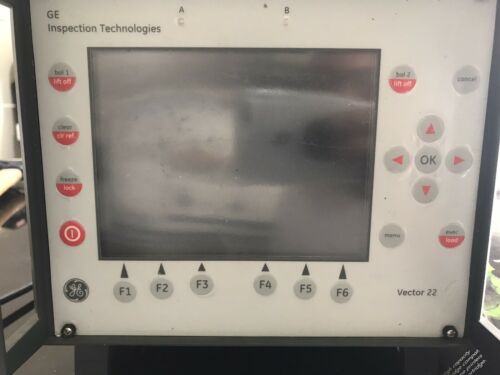

GE Inspections Hocking Vector 22 Dual Frequency Eddy Current Inspection System

$ 528

- Description

- Size Guide

Description

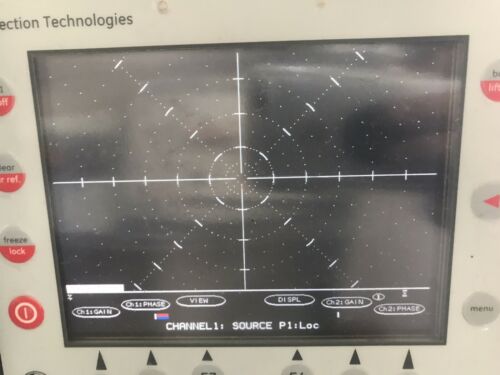

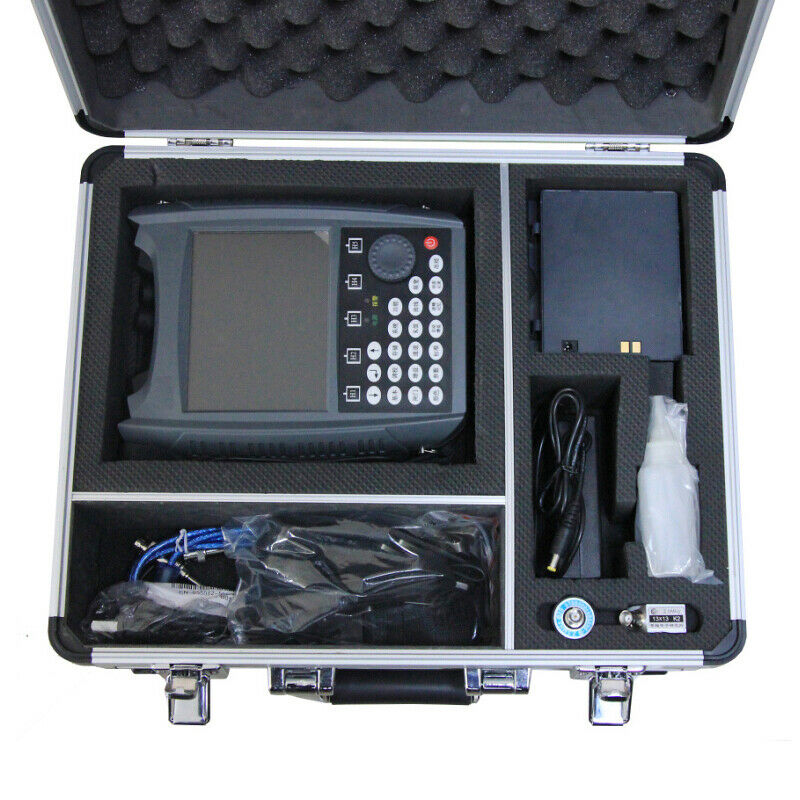

Slightly used GE Inspections Hocking Vector 22 Dual Frequency Eddy Current Inspection System. This unit is flawless and works great.The Vector 22 is a dual-channel eddy current instrument that features two sensor inputs each with its own independent test channel. Encircling, rotating, and probe type sensors can be connected. It is intended for installation in automated or semi-automated testing lines for crack detection, heat treat verification, and feature detection. It is also an ideal instrument for bench-top and laboratory use.

Products Features

Dual probe, dual-channel or single probe dual-frequency instrument

Separate alarm outputs for each test channel / test frequency

Configurable probe connections (bridge, reflection, absolute)

Supports rotating probe drives

Wide range of filtering for dynamic applications

Flexible I/O interface for connection to process controllers (PLCs)

Multi-lingual user interface

Internal storage of settings and signal traces

Applications

Detection of surface cracks in manufactured components

Heat treat sorting with encircling coils or probes

Surface inspection of non-ferrous bar, wire, and tubing using encircling coils

Surface inspection of rotating ferrous or non-ferrous bars and tubes using fixed probes

Inspection of the weld zone of ferrous and non-ferrous welded tubes using fixed probes

Inspection of boreholes or flat surfaces using rotating probes

Thread detection and other test piece feature detection applications

Rail inspection

Advantages of the Vector 22

The Vector 22 uses the Eddy Current Technique, which has some key real-world advantages for manufacturers of quality products;

•

Sensitive:

The Vector 22 is a highly economic and effective technique for coverage of surface and near surface flaws in metals, covering areas that Ultrasonic cannot inspect .

•

Speed:

The Vector 22 has a 16kHz sample rate which allows for very high line speeds, especially when compared to alternative techniques such as X-ray or ultrasonic. Eddy Current has no waste product, or couplant requirement - significantly simplifying the management process.

•

Scaleable:

The ability to add extra channels as required gives a fully scaleable solution, and because of the Vector 22’s extensive Inputs and outputs, interfacing with parts handling can be as simple or as sophisticated as required

•

Surface Tolerant:

The ability of Eddy Current to inspect through paint and other non-conductive surface coatings means that preparation for inspection is minimal. The probe can even inspect without contact with the part.

Basic Specifications

Display

6.5” (165mm) VGA Color display with CCFT Backlight. Selectable color for each channel.

Frequency Range

50 Hz to 10 MHz

Low Pass Filters

20 Hz to 5 kHz

High Pass Filters

DC, Ultra 0.01 Hz to 0.5 Hz, Normal 10 Hz to 2 kHz

Channels/Probes

2 per unit. Up to 8 Vector 22 units can be synchronised using optional synchronisation unit

Temp. Range

32°F to 122°F (0° to 50°C)

Max. Dimensions

Dimensions in case (without feet)

9.2” x 7” x 10” 235.4mmWx177mmHx255mmD

Power

90 - 264V (47-63 Hz, 440 Hz). No battery options.

Alarms

Independent on each channel. Choice of Sector, Level or Box Gate alarm.

Alarm Stretch

Range from 50mS to 10 seconds

Alarm Delay

Menu Selectable from 0.1 to 9.5 seconds

Balance

Independent or Combined for each probe. Seperate front panel balance keys. Remote balance.

Trace Record/Replay

Up to 30 seconds of trace internally recordable.

Internal Relays

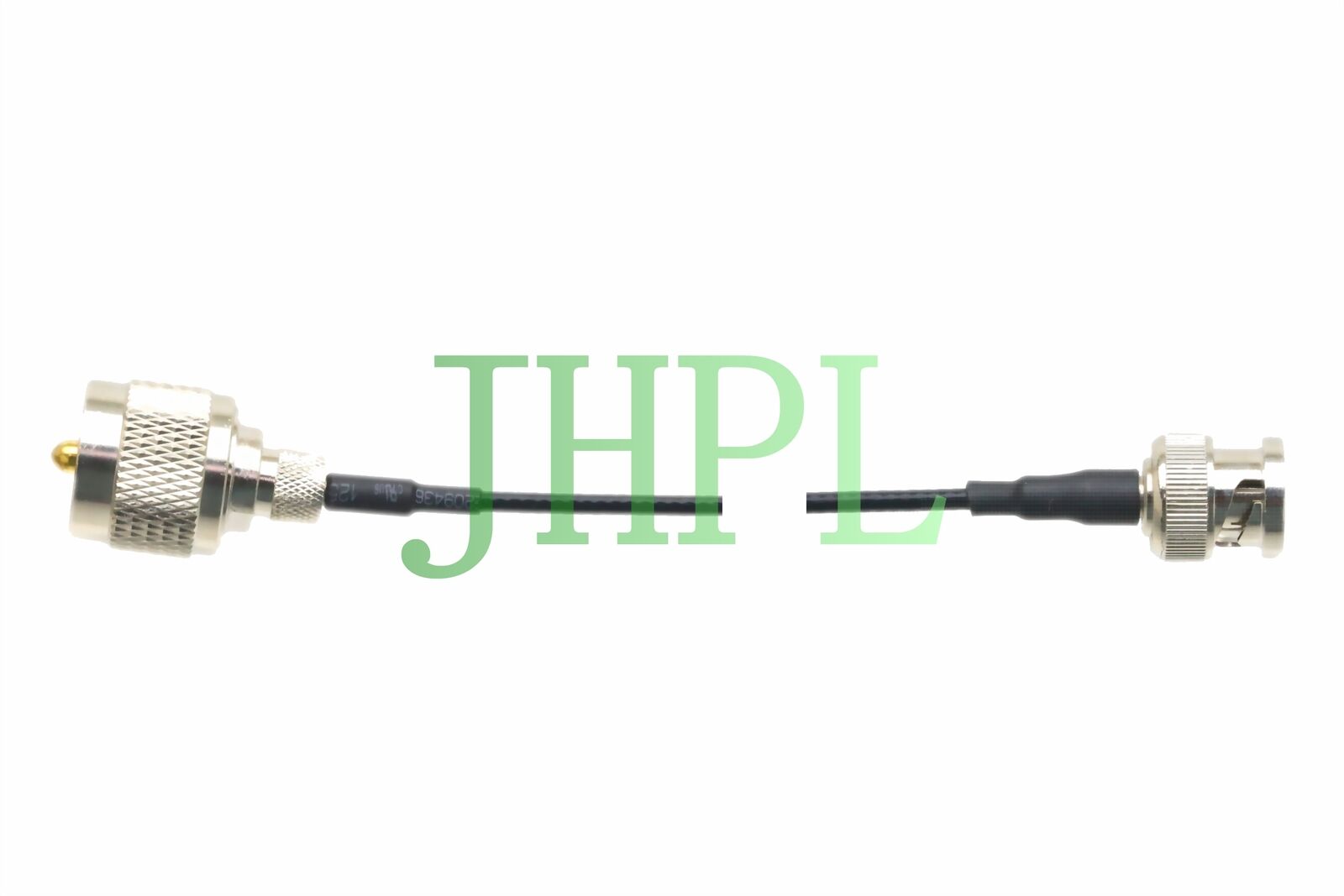

AC or DC chosen at time of order. Amphenol connector on rear of unit, mating items available as accessories.

Analog Out

6 Independantly selectable Analog outputs.

Synch Input

Via RJ45 connector to rear panel

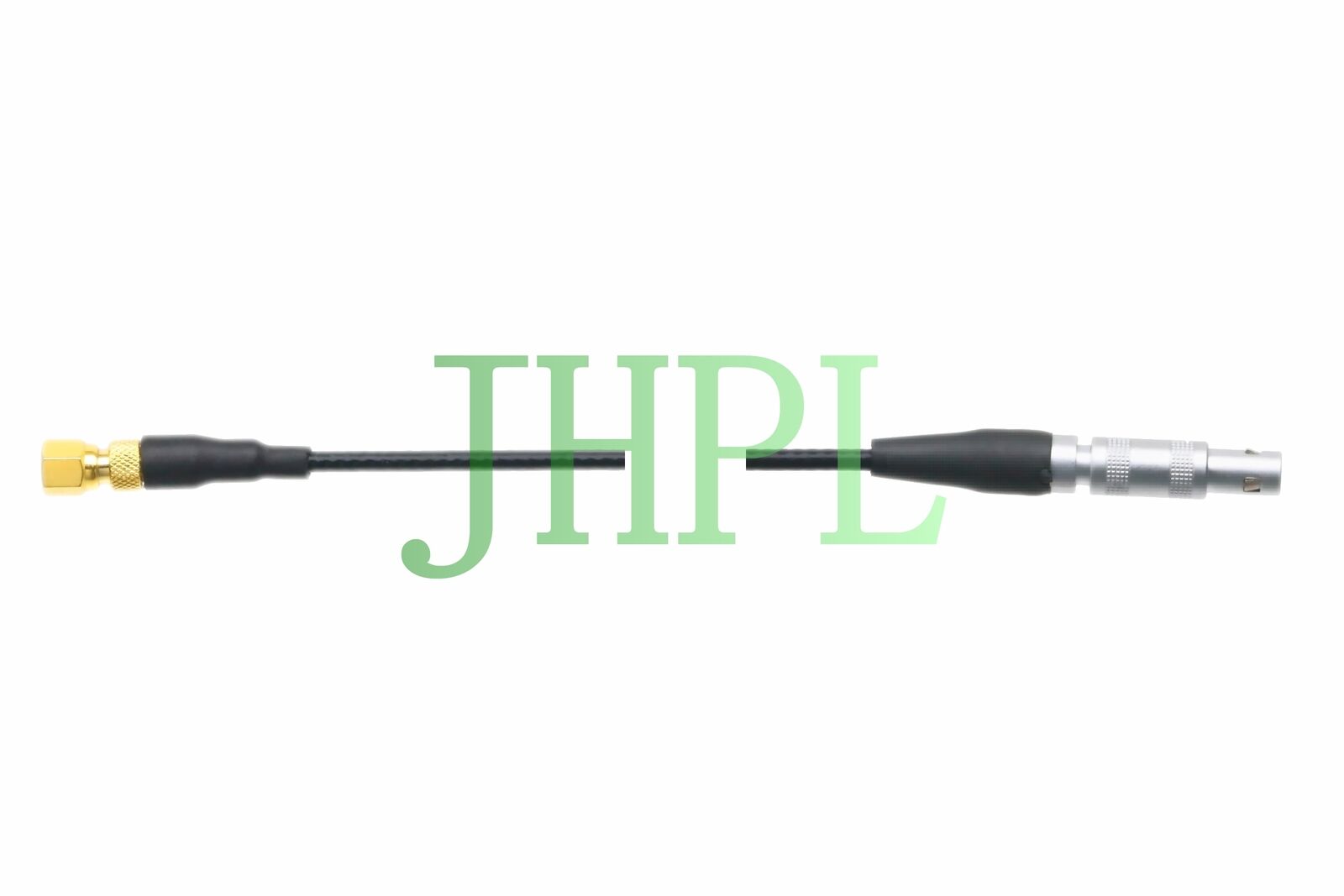

Probe Connectors

Lemo size 4, 16 Way connector

RS232 Provided on 9 way D Type for Standard I/O

Auto Power On

User Defined option using internal link to power on when power is applied.

VECTOR 22 BASE INSTRUMENT INCLUDES

:

Industrial Benchtop Housing

AC Power Cord